When talking about aseptic conditions we mean being able to supply on the market safe and 100% sterile products in aseptic containers. The aseptic technology enables the packaging to be completely clean and free of chemicals and to keep the foods safe preserving its colour, consistency, taste and nutritional values.

How does the standard aseptic process work?

The standard aseptic process includes sterilization of the bottles, (inside and outside) before the filling process, and implies the use of chemicals such as oxonia (peroxyacetic acid / hydrogen peroxide) and rinsing with water after treatment.

This process can be complicated with plastic bottles that have particular shapes. In such cases it can be difficult to guarantee the absence of chemical residues, that could alter the final taste of the product, after the treatment.

In order to avoid this problem, many companies chose a technology that allows directly feeding the bottling machine with sterile bottles, without having to rinse them internally.

How does Techne’s aseptic process work?

The principle of aseptic blowing was developed on Techne’s blowing extrusion machines in 1992 and is mainly used for the DAIRY and PHARMA sector.

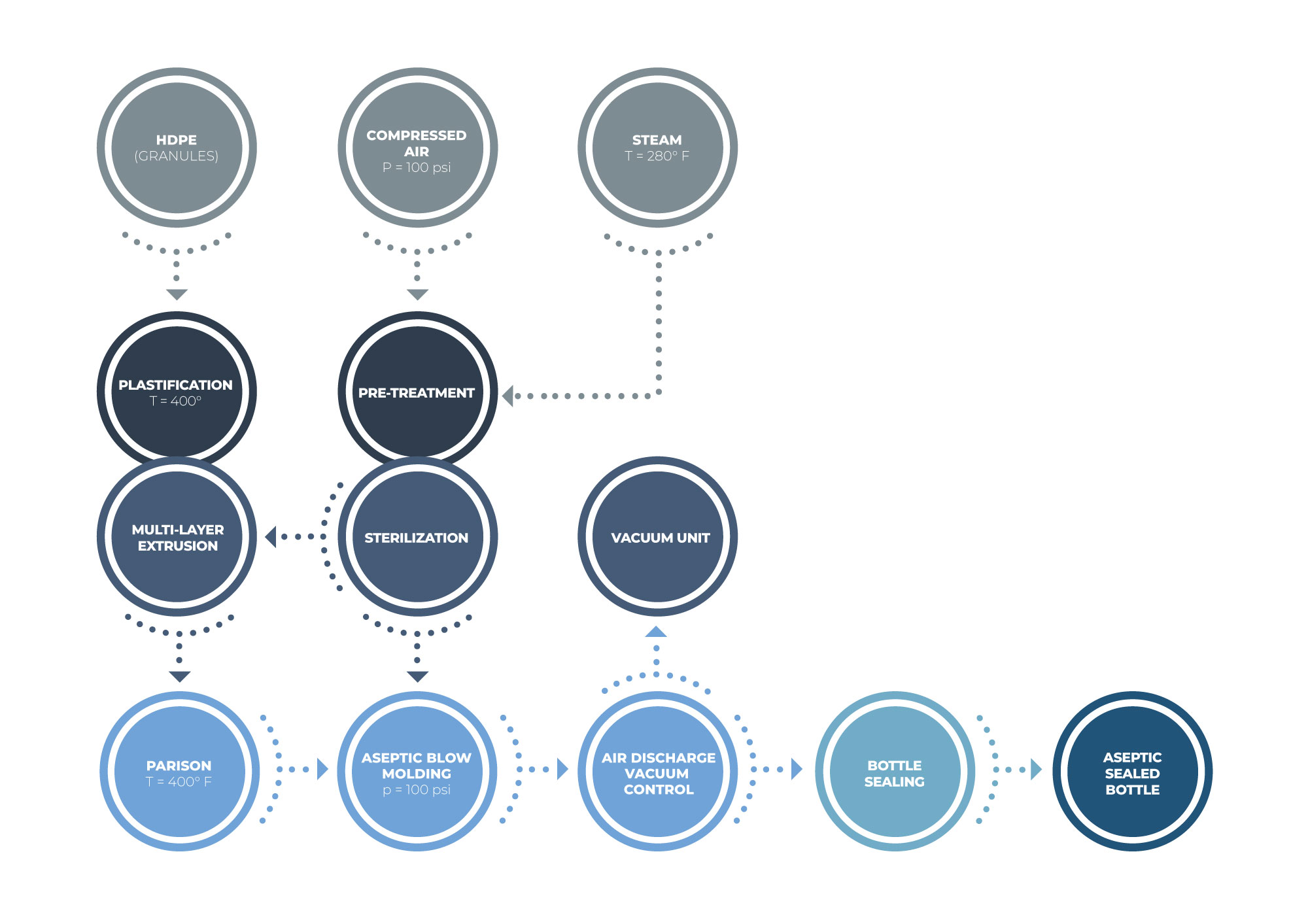

This aseptic process is in itself quite simple since it’s based on a specific dedicated system that uses steam to sterilize the blowing machine. This sterilization system is suited to all Techne’s blowing machines.

This sophisticated system filters the air used to mold the bottles and uses only steam to sterilize the air piping circuit, therefore avoiding chemical agents.

The end result is a sealed and sterile bottle that does not need to be internally rinsed and is ready for storage or to be sent to the sterile chamber for the remaining part of the process, depending on the customer's needs.

Key points of Techne’s aseptic process:

- To maintain the machine’s aseptic conditions it is necessary to periodically do a steam sterilization cycle. Turning the machine on and off does not imply the loss of its aseptic conditions;

- There’s a significant reduction in the size of the filler, and therefore in the overall space of the entire line, as only external washing of the bottle is provided before the domo is removed;

- Cost reduction thanks to the recovery of kinetic energy.

Which are the advantages of producing an aseptic plastic bottle?

- The molded bottle is already sterile;

- There is no need to use chemical agents that may alter the flavor and organoleptic properties of the content;

- The dome, the part sealed above the bottle neck, provided an high resistance to the container, useful in case of bottles storage in silos.

For more information please take a look at the video above. Download the brochure to learn more.